Mobile Device Industry

The electronic communication industry is changing with each passing day. With the application and popularization of 5G high-frequency technology, related electronic communication equipment has constantly been introduced, and it has also driven the required electronic parts to be replaced with new ones. Therefore, we need to keep up with the changes in the industry. The pace requires more efficient R&D and production schedules to strive for higher market competitiveness. We are dedicated to electronic precision manufacturing services, we are able to offer OEM electronic parts design according to the demands of customers.

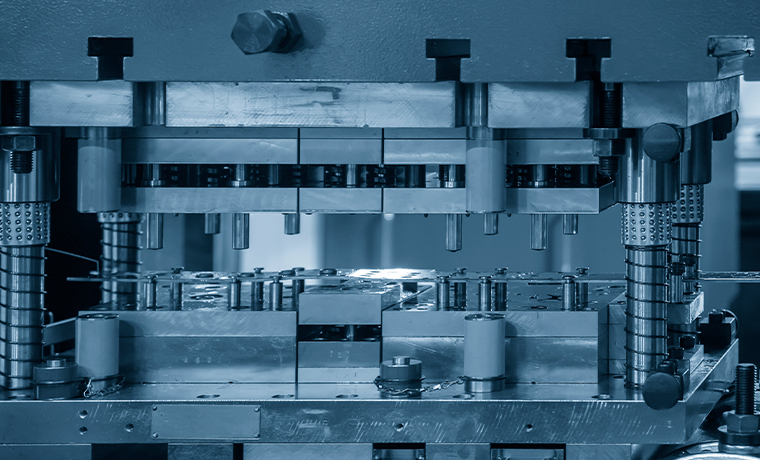

The high precision requirements of the products of the electronic communication industry require higher specifications. Electronic precision parts are of more complicated designs and can be developed, sampled, and produced by using mold stampings or injection molding processes. Chan Way can undertake the related aircon electronic precision manufacturing services and can conduct soft molds (simple molds) production and test molds for new products to assist customers in product proofing and modification plan discussed in the development stage, continue to expand the mold mass production and shorten the mold development cycle to improve work efficiency. Finding a reliable OEM electronic parts manufacturer? Contact us, we are willing to offer you better electronic precision manufacturing services.

OEM Case for Communication/ Server Industry

Metal stamping die, high-speed router, smartphone device, electrical connector, IC/ LED precision parts, connecting piece for battery module, information terminal connector, optical module, connector, and mechanical parts of cloud server.

Overview of Foundry Capabilities of Communication Mobile Device Products

Mold Materials

CF-H40S、KD20、G4、G5

Mold Insert Machining Accuracy

±0.002mm

Processing Technology-Wire cutting

- Minimum wire diameter:φ0.03

- Minimum R angle:R0.03

- Surface roughness:Ra 0.1

Processing Technology:Optical grinding

- Surface roughness:Ra 0.1

- Minimum R angle:R 0.03

Standard Parts Manufacturer

FUTABA、HASCO、MISUMI

Punching Ability

- Tonnage of Stamping Equipment:30~60ton

- Maximum Punching Speed:1000spm

- Stamping Die Size

Maximum:1300x600x280mm

minimum:150x150x150mm